Panel F

Single-component, quick-hardening polyurethane adhesive for bonding plasterboard and insulation panels.

Single-component, quick-hardening polyurethane adhesive for bonding plasterboard and insulation panels.

Application areas

Discover more

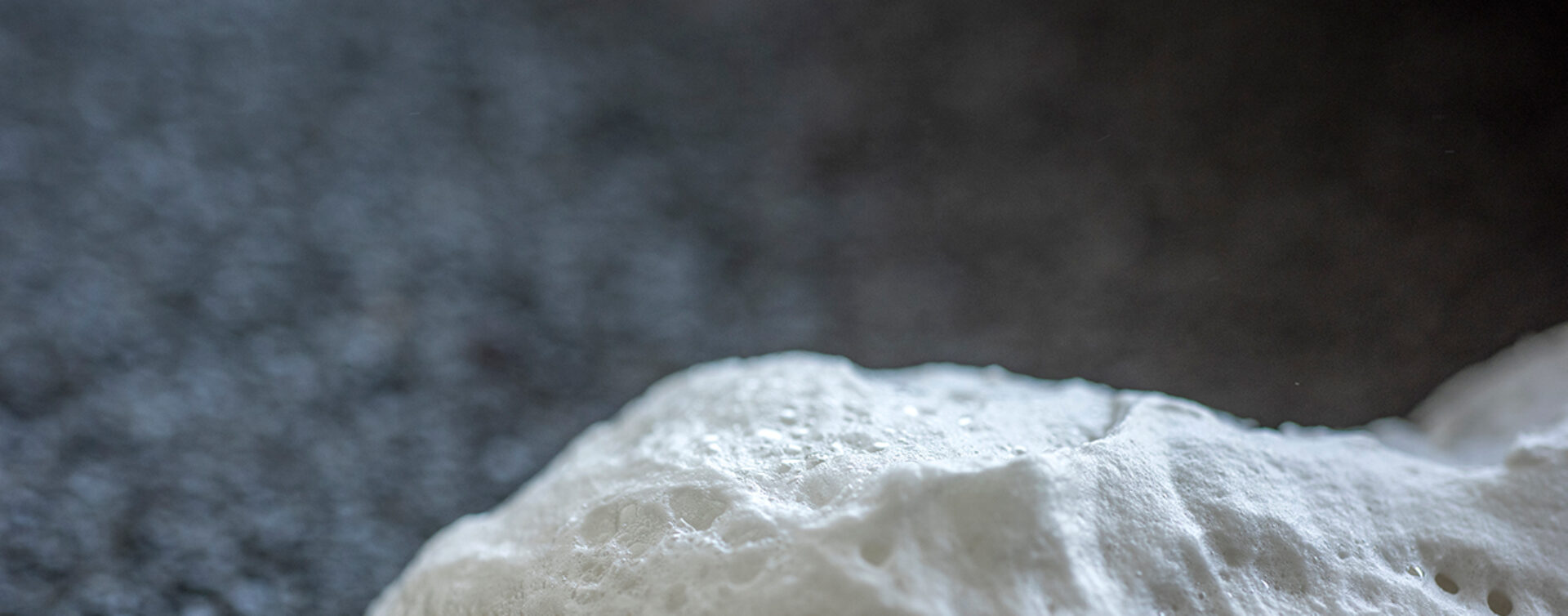

PU Foam Panel F is a one component, quick-hardening polyurethane adhesive, packaged in an aerosol can, specifically developed and tested for bonding various types of insulation panels for underfloor perimeter insulation and thermal insulation applications in general. The reduced post-expansion and the high texture and adhesion of the fresh adhesive make it possible to install panels of various types with different thickness, such as EPS, XPS, PU, rock or glass wool, etc., on various types of substrates (mineral substrates, brick, concrete, plaster, wood, metal, glass, plastic, slated or aged/oxidised bituminous membranes) in accordance with the ETAG 004 tests for external thermal insulation systems. It can be used to fill cracks that may occur during the installation of the boards. Its particularly homogeneous and fine cell structure contributes to acoustic and thermal insulation without creating any discontinuity. Despite the excellent performance of PU Foam Panel F in terms of technical and application characteristics in the installation of external thermal insulation systems, traditional mechanical fastening systems (dowels, etc.) that guarantee the anchorage of the boards through the thickness of the substrate are still needed to prevent the risk of adhesive detachment in case of insufficiently solid and consistent surfaces.

The substrates must be free of oil, grease and dust. Especially in the case of application on non-porous substrates, it may be useful to dampen the substrates beforehand in order to provide the fresh product with the necessary humidity, for complete curing.

Cleaning

Any traces of non-hardened PU Foam Panel F, e.g. on clothing, window frames, etc., can be cleaned with Cleaner for PU-foams. The hardened product can only be removed mechanically (scraping or grinding). Possible residues in the valve can be easily removed when it has fully hardened. This product contains flammable components, so use only in well-ventilated areas.

Store in a cool place in an upright position. Storage in a horizontal position quickly leads to incrustations under the valve which irreparably compromise the extrusion of the adhesive. PU Foam Panel F is stable for at least 12 months when stored upright, in a cool and dry place (between 15 and 25 °C) and in its original unopened packaging.

Panel F, although extremely valid from a technical-application and performance point of view in the laying of coatings, does not exclude the traditional mechanical sealing systems (dowels, etc.) which guarantee the anchorage of the panels in the thickness of the substrate to prevent the risk of adhesive detachment should the surface not be sufficiently solid and consistent.

In case of bonding on new bituminous membranes, prefer Bitumen Seal adhesive/sealant.

The Panel F can is a pressurised container. Please read the information on the safety data sheet carefully.

| Color | Code | Application | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|---|

| Natural yellow | 5558 | Gun application | can | 12x750 ml |

42 cardboards

|

| PARAMETER | VALUE |

| Colour | green |

| Outdoor temperature during application | from +5 °C to +35 °C |

| Operating temperature | from -40 °C to +120 °C |

| Surface film formation (at 23 °C and 50% r.H.) (MIT 98*) | 3 minutes |

| Shearing (bead of 20 mm diameter at 23 °C and 50% r.H.) (MIT R/8*) | 9 minutes |

| Density (after contrasted expansion) (MIT 50*) | 14–16 kg/m3 |

| Post-expansion % bead | 18-20 |

| Volume yield (litres) | 46-50 |

| Surface of installed panels (m2) | 12 |

| Dimensional change (23 °C – 50% r.H.) (MIT 52*) | <3% |

| Adhesion to polystyrene (ETAG 004) | 0,2 N/mm2 (panel breakage) |

| Fire behaviour (DIN 4102) | B3 |

| UV resistance | poor, tends to yellow |

* Torggler’s Internal Methods (MIT) are available on request.

Adhesive yield is highly dependent on spray can and ambient temperatures. At low temperatures, both the pressure at which the fresh material escapes from the valve and the yield of the hardened product are greatly reduced. In order to obtain a good yield, we recommend a spray can temperature of approx. +20 °C. Consumption depends on the type of elements to be installed and the installation method: approximately one spray can glues 8 to 12 m2 of insulation panels and up to 3 plasterboard panels. The values indicated refer to laboratory conditions and may vary considerably depending on the actual application and environmental conditions.

Contact our team for personalized support and product guidance.