Espansol Ancor

Pre-mixed, fluid, self-levelling cementitious mortar for anchoring and precise grouting works.

Pre-mixed, fluid, self-levelling cementitious mortar for anchoring and precise grouting works.

Discover more

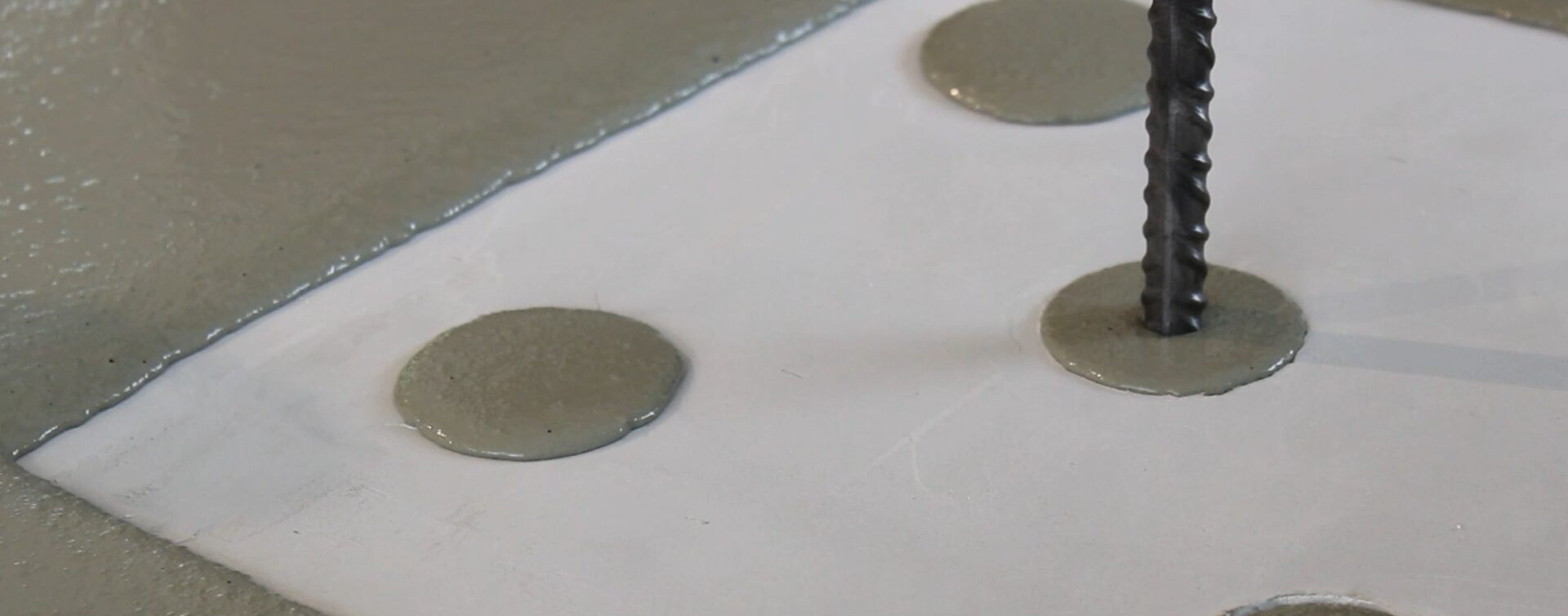

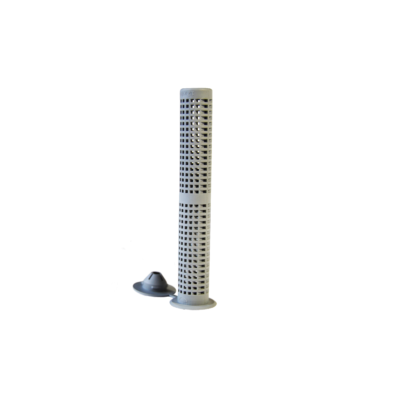

Espansol Ancor is super-fluid, non shrinking, pre-mixed mortar with a very high initial and final mechanical resistance. It is especially suitable for anchorage and placement applications. Highly fluid with controlled expansion ensure that this mortar can fill all gaps perfectly and has a high adhesive power. Although the mortar is fluid, its components are strongly cohesive and do not tend to separate. It does not contain metallic aggregates, chloride aggregates or aluminium cements. Espansol Ancor conforms to the specifications of EN 1504-6 for mortars for anchoring reinforcing steel. It can also be used as a R4 type hydraulic mortar (PCC) for the structural repair of concrete structures as per the standard EN 1504-3.

When used as a structural repair mortar as per EN 1504-3, the field of application of Espansol Ancor conforms to the principles 3 (Concrete restoration), 4 (Structural strengthening) and 7 (Preserving or restoring passivity) of EN 1504-9 using the following methods 3.1 (Applying mortar by hand), 4.4 (Adding mortar or concrete) and 7.1 (Increasing cover to reinforcement with additional cementitious mortar or concrete).

Preparation

The substrate must be clean and well keyed. Provide wide enough filling and escape openings. The day before casting, wet the substrate until the water stops soaking in.

Mixing the product

Mix Espansol Ancor with approx. 13-14 % water (approx. 3,25 – 3,50 litres for a 25 kg bag) to the consistency required. Do not exceed the recommended maximum quantity. Pour approximately 3⁄4 of the total amount of water into the cement mixer. Add Espansol Ancor pouring it in uniformly and continuously. Mix until smooth and free of lumps. Then add the rest of the water until you obtain the required consistency. Pot life is approximately 30 minutes at 20 °C. Higher temperatures reduce pot life. Wet the surface again until it is saturated. Allow the excess water to evaporate or remove it with a sponge.

Application

Pour the mixture into the forms smoothly and from one side only so that the air can escape from the other side. Fill narrow or awkward gaps with the aid of iron rods or bars. Do not vibrate. For cavities larger than 5 cm, dilute the Espansol Ancor with 50 % by weight of fine gravel (3 – 7 mm) i.e. 2 parts Espansol Ancor to 1 part fine gravel. In practical terms this means 3 buckets of fine gravel for every 100 kg (equal to four 25 kg bags) of Espansol Ancor. This changes some of the characteristics of the product such as the amount of water required for the mix which is reduced from approximately 13 % of the product to approximately 10 % of the product when diluted with gravel. Mechanical performance in terms of compression resistance is reduced by approximately 10 % to somewhere in the order of 65 MPa. To prevent cracking caused by too rapid evaporation of the water during hot weather and to promote expansion to compensate for shrinkage, keep the exposed parts of the casting wet for at least 48 hours and protect from wind and direct sunlight. For surface finishing, follow the general rules of good practice for the application of cementitious mortars. As with all cement-based products, do not apply at temperatures below +5 °C.

Cleaning

The tools used for application can be cleaned with water before the mortar hardens; afterwards, cleaning can only be done by mechanical removal.

Store in a dry, covered place. Unopened in its original bags, the product can be stored for at least 12 months. Protect from moisture.

| Color | Code | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| Grey | 6032 | bag | 25kg |

50 bags

|

Precision anchorage and placement:

| PARAMETER | EN 1504-3 / EN 1504-6 REQUIREMENT | VALUE |

| MEASURED ON POWDER PRODUCT | ||

| Consistency | powder | |

| Grain size (EN 12192-1) | 0-2 mm | |

| Water soluble chlorides (EN 1015-17) | ≤ 0,05 % | < 0,01 % |

| MEASURED ON FRESH MIX | ||

| Mixing water | 13-14% | |

| Density of mix when fresh (EN 1015-6) | 2,220 kg/l | |

| Mix consistency | visual | fluid |

| Setting times (EN 196-3) start | approx. 5 hours | |

| Setting times (EN 196-3) end | approx. 10 hours | |

| Mix pot life (EN 13395) | > 30 minutes | |

| Free expansion in plastic phase (UNI 8996) | 0,5% | |

| Impeded expansion (UNI 8147): at 24 hours | 0,0130% | |

| Impeded expansion (UNI 8147): at 28 days | 0,0250% | |

| Application temperature | +5 °C to +30 °C | |

| MEASURED ON HARDENED PRODUCT | ||

| Operating temperature | -20 °C to +90 °C | |

| Compression strength at 1 day (EN 12190) | ≥ 35 MPa | |

| Compression strength at 7days (EN 12190) | ≥ 65 MPa | |

| Compression strength at 28 days (EN 12190) | ≥ 45 MPa | ≥ 80 MPa |

| Bending strength at 1day (EN 121909) | ≥ 5 MPa | |

| Bending strength at 7 days (EN 121909) | ≥ 8 MPa | |

| Bending strength at 28 days (EN 121909) | > 9 Mpa | |

| Compression modulus of elasticity (EN 13412) | ≥ 20 GPa | > 30 Gpa |

| Adhesion by pull-off test (EN 15429) | ≥ 2,0 MPa | > 2,0 Mpa |

| Carbonation resistance (EN 132959) | dK ≤ control concrete | dK = 0 mm (no CO2 penetration) |

| Impeded shrinkage/expansion (EN 13687-4) | Adhesion after test: ≥ 2,0 MPa | > 3,0 Mpa |

| Thermal compatibility (freeze-thaw cycles with salts) (EN 13687-4) | Adhesion after 50 cycles: ≥ 2,0 MPa | > 2,5 MPa |

| Capillary absorption (EN 13057) | ≤ 0,5 kg/(m2*h0,5) | 0,15 kg/(m2*h0,5) |

| Pull-out (EN 1881) | Movement at 75 kN: ≤ 0,6 mm | < 0,4 mm |

| Fire reaction class (EN 13501-1) | Value declared by the producer | Class A1 |

| Classification (EN 1504-3) | R4 PCC | |

Consumption is approximately 2100 kg/m3.

Contact our team for personalized support and product guidance.