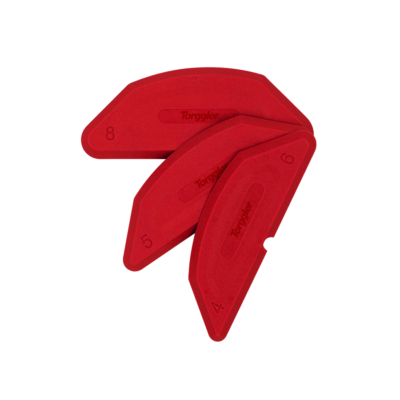

Strong

Super strong, hybrid polymer adhesive with high initial tack for indoor and outdoor applications. No need of external mechanical fixture during hardening.

Super strong, hybrid polymer adhesive with high initial tack for indoor and outdoor applications. No need of external mechanical fixture during hardening.

Application areas

Discover more

Strong is a high-quality professional adhesive with a very strong initial adhesion which hardens by reaction with moisture, forming a permanently elastic mass. The product does not shrink or swell. It is free of isocyanates, solvents and silicones, does not produce substances which can corrode metal and does not emit unpleasant odours. The product awarded the EC 1 Plus label by the GEV association for very low emissions of volatile organic compounds.

Application temperature of both the environment and the materials can vary from +5 to +40 °C. Substrates must be solid, clean and free of oils or dust.

Cleaning of tools

While the material is in the plastic state use solvents; following setting clean only mechanically. For further information contact Torggler technical assistance.

Hybrid Adhesive Strong must be stored in a shaded place at between +5° and +25 °C. Stored in these conditions the sealed product will keep for at least 18 months.

Hybrid Adhesive Strong is not suitable for: PE, PP, PMMA, PTFE, polycarbonate, soft plastic materials, neoprene and bituminous surfaces. Do not use in contact with chlorine (swimming pools). It is not suitable for use as a sealant: for connection joints Hybrid Adhesive General Use is preferred; in the case of dilation joints, however, we recommend use of a silicone-based sealant with a low modulus of elasticity, such as Silicone Low Modulus.

| Color | Code | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| White | 8007 | cartridge | 12x290 ml |

104 cardboards

|

| PARAMETER AND REFERENCE STANDARD | VALUE |

| Base | hybrid polymers |

| Density (ISO 1183-1) | 1,6 g/ml |

| Application temperature | from +5 °C to +40 °C |

| Skin-over time (MIT 33*) | 5-10 minutes |

| Hardening rate from the outside to the inside at 23 °C (MIT 32*) | approx. 2 – 3 mm/24 h |

| Operating temperature | from -40 °C to +90 °C |

| Shore A hardness (ISO 868) | 55 |

| Elongation at break (DIN 53504 S2) | 300% |

| Modulus of elasticity at 100% (DIN 53504 S2) | 1,4 N/mm2 |

| Failure load (DIN 53504 S2) | 2,2 N/mm2 |

| Extrusion speed (MIT 030*) | approx. 1 g |

| Initial shear strength (EN 12004-2 point 4) | 1,16 N/mm2 |

| Shear adhesion strength after water immersion EN 12004-2 point 4 |

0,6 N/mm2 |

| Shear adhesion strength after action of heat (EN 12004-2 point 4) | 1,21 N/mm2 |

| Mass variation (MIT 057*) | 2% |

| Volume variation (MIT 057*) | 4% |

| Creep resistance (ISO 7390) | < 2 mm |

| Frost resistance during transport | down to -15 °C |

* The Torggler Internal Methods (MIT) are available on request.

Contact our team for personalized support and product guidance.