Ekomix

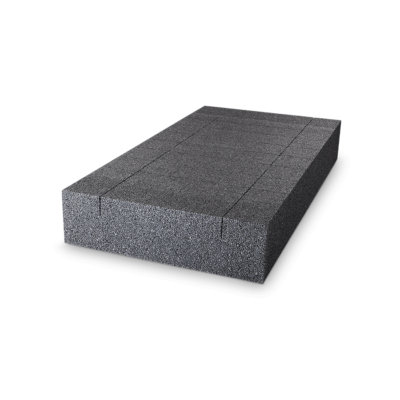

Powder finishing mortar and adhesive made of cement, selected mineral aggregates, additives. For bonding and rendering polystyrene insulation panels. Component of the Ekomix EPS system.

Powder finishing mortar and adhesive made of cement, selected mineral aggregates, additives. For bonding and rendering polystyrene insulation panels. Component of the Ekomix EPS system.

Variations

Application areas

Discover more

Preparation for use

The substrate must be dry, not frozen, free of dust, efflorescence, not water-repellent and solid. The wall flatness must be within the tolerances prescribed by ÖNORM DIN 18202.

Product preparation

Mix Ekomix with approx. 6.00-6.25 litres of clean water per 25 kg bag (0.24-0.25 litres of water per 1 kg powder) in a clean container and stir constantly using a low speed mortar mixer (max. 500 rpm) until the mixture is homogeneous and then leave to stand for approx. 5 minutes. Mix again and, if necessary, correct the consistency with a small amount of water. Do not add other substances to the product.

Instructions for use

For bonding insulation panels: apply the adhesive using the dot and stripe method (bonding surface approx. 40 %). Strip width approx. 4 cm, height approx. 2 cm.

Rendering of insulation panels: apply the render approx. 2-3 days after bonding (depending on the weather conditions and any additional dowelling) in a minimum thickness of 3 mm and then spread with a toothed trowel. Bury the T50 reinforcement mesh in the render bed; at the joints overlap by at least 10 cm and cover it completely with the trowel. When the render is completely dry (maximum 7 days depending on the weather conditions), the suitable Torggler EKOR wall coating can be applied.

The mixture workability time is about 2 hours. Material left in open containers should no longer be used or mixed with fresh material.

During the processing and drying step, the temperature of the surrounding environment and the substrate must not fall below +5 °C. Protect against frost, too fast drying (direct beating sun, wind) and subsequent humidity (rain) until completely dry.

Store Ekomix in a dry and sheltered place. In the original closed bags it is kept for at least 12 months. PROTECT FROM HUMIDITY.

Ekomix, in its grey version, is admixed with a special reducing agent to ensure compliance with the limit concentration of 0.0002% (2 ppm) of water-soluble hexavalent chromium (in relation to the weight of the Portland cement contained). See the information on the packaging according to Directive 2003/53/EC.

| Color | Code | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| White | 5428 | bag | 25kg |

50 bags

|

|

| Grey | 5427 | bag | 25kg |

50 bags

|

Ekomix is suitable for:

| Product | Ekomix White | Ekomix Grey |

| Appearance | white powder | grey powder |

| Mixing water | 24-25% (6.00-6.25 l per 25 kg bag) | 24-25% (6.00-6.25 l per 25 kg bag) |

| Particle size | ≤0.8 mm | ≤0.8 mm |

| Workability time | 2 hours | 2 hours |

| Adhesion on concrete | ≥ 0.6 MPa | ≥ 0.6 MPa |

| Adhesion on polystyrene | ≥ 0.08 MPa | ≥ 0.08 MPa |

| Application temperature | from + 5 °C to +25 °C | from + 5 °C to +25 °C |

| Thermal resistance | -30 °C to +80 °C | -30 °C to +80 °C |

The consumption of Ekomix depends on its application.

As adhesive: from 4 to 5 kg/m².

As a skim coat: from 3 to 4 kg/m².

Contact our team for personalized support and product guidance.