Mastofix® Hydro Light

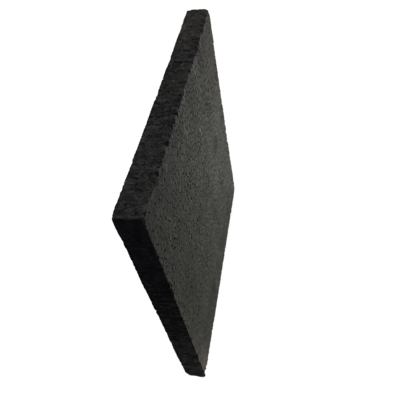

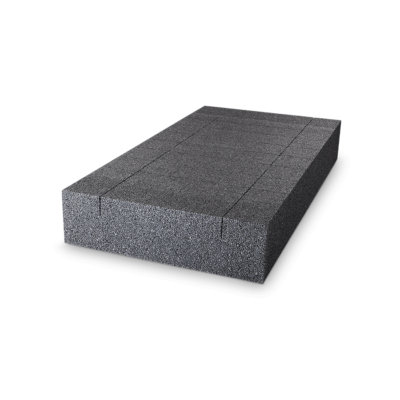

Hydrophobised skimming adhesive in powder form based on cement, selected mineral aggregates, EPS spheres, additives. For bonding and skimming EPS insulation boards, MW rock wool, and PIR foamed polyiso foam.

Hydrophobised skimming adhesive in powder form based on cement, selected mineral aggregates, EPS spheres, additives. For bonding and skimming EPS insulation boards, MW rock wool, and PIR foamed polyiso foam.

Discover more

Preparation for laying

The substrate must be dry, frost-free, free of dust, efflorescence, not water-repellent and solid.

Product preparation

Mix Mastofix Hydro Light with approx. 6 – 6.25 litres of clean water per 20 kg bag in a clean container and stir constantly using a slow-running mortar mixer (max. 500 rpm) until the mix is homogenous and then allow to stand for approx. 5 minutes. Mix again and, if necessary, correct the consistency with a small amount of water. Do not add any other substances to the product.

Application instructions

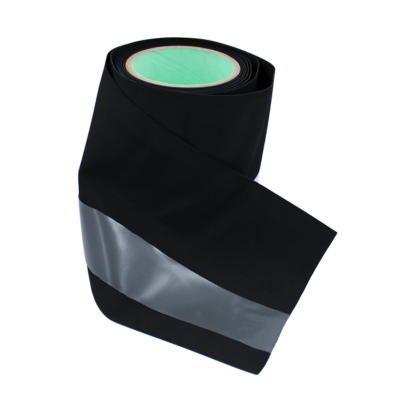

Bonding the insulation panels: apply adhesive using the dot-and-strip method (bonding area approx. 40%). Strip width approx. 5 cm, height approx. 2 cm. Levelling of the insulation boards: Apply levelling compound approx. 2 – 3 days after gluing (depending on weather conditions, additional dowelling may be necessary) in a minimum thickness of 3 mm and then spread with a notched trowel T 16. Bury the reinforcement mesh Rete SSA-1363-160 in the levelling bed (outer third); overlap at joints by at least 10 cm and completely cover with the trowel. When the plaster is completely dry (maximum 7 days depending on weather conditions), the suitable Torggler eTics wall coating can be applied. The pot life of the mix is approx. 4 hours. Material remaining in open containers must not be used or mixed with fresh material. During processing and drying, the ambient and substrate temperature must not fall below +5 °C. Until completely dry, protect against frost, excessively fast drying (direct sunlight, wind) and subsequent moisture (rain). Baseboard insulation panels, coated with a system adhesive and wall covering, must be sealed with Torggler Flex 1K or Flexistar in the area below ground level up to approx. 10 cm below the lower end of the skim coat and up to max. 5 cm above ground level (finish with baseboard profile). The relevant national standards must be observed in all cases.

See information on the packaging according to Directive 2003/53/EC. Store Mastofix Hydro Light in a dry and sheltered place. In the original unopened bags it will keep for at least 12 months. Protect against moisture.

| Color | Code | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| White | 8375 | bag | 20kg |

50 bags

|

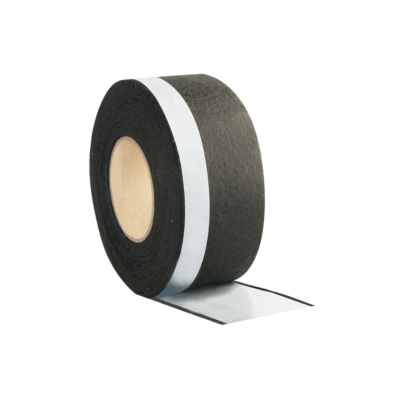

Mastofix Light is suitable for:

| PARAMETRI | VALORI |

| Aspetto | Polvere bianca con sfere in EPS |

| Acqua di impasto | 30% (6,00-6,25 l per sacco da 20 kg) |

| Granulometria | 1,2 mm |

| Tempo di lavorabilità | 2 ore (T: 23 ⁰C; U.R 50%) |

| Adesione su calcestruzzo | 1,0 N/mm² |

| Adesione su polistirolo | 0,08 N/mm² |

| Consumo incollaggio | 3-4 kg/m² |

| Consumo rasatura | 5-6 kg/m² |

| Massa volumica (indurito) (kg/m³) | ca. 1200 |

| Capacità termica specifica Cp (J/(kgK)) | ca. 1000 |

| Permeabilità al vapore μ | 20 |

| Conducibilità termica λ10, dry (EN 1745:2012) | 0,36 W/mK (valore tabulare) per P=90% |

| Modulo elastico (GPa) | 3 |

| Resistenza alla flessione (MPa | ≥2 |

| Resistenza alla compressione (Mpa) | ≥10 |

| Assorbimento capillare (EN 1015-18) | 0,12 kg/m² min0,5 |

| Temperatura di applicazione | da +5 °C a +30 °C |

| Tempo di asciugatura (23⁰ C/50% U.R) | ca. 7 gg |

| Spessore della rasatura | 3 mm |

| Reazione al fuoco | NPD |

As a coating approx. 5-6 kg/m², as an adhesive approx. 3-4 kg/m². Indicative figure, depending on the flatness of the substrate.

Contact our team for personalized support and product guidance.