Multigrip

Multigrip is a single component, adhesion promoting primer, based on a styrene-acrylic resin water based emulsion and selected aggregates.

Multigrip is a single component, adhesion promoting primer, based on a styrene-acrylic resin water based emulsion and selected aggregates.

Application areas

Discover more

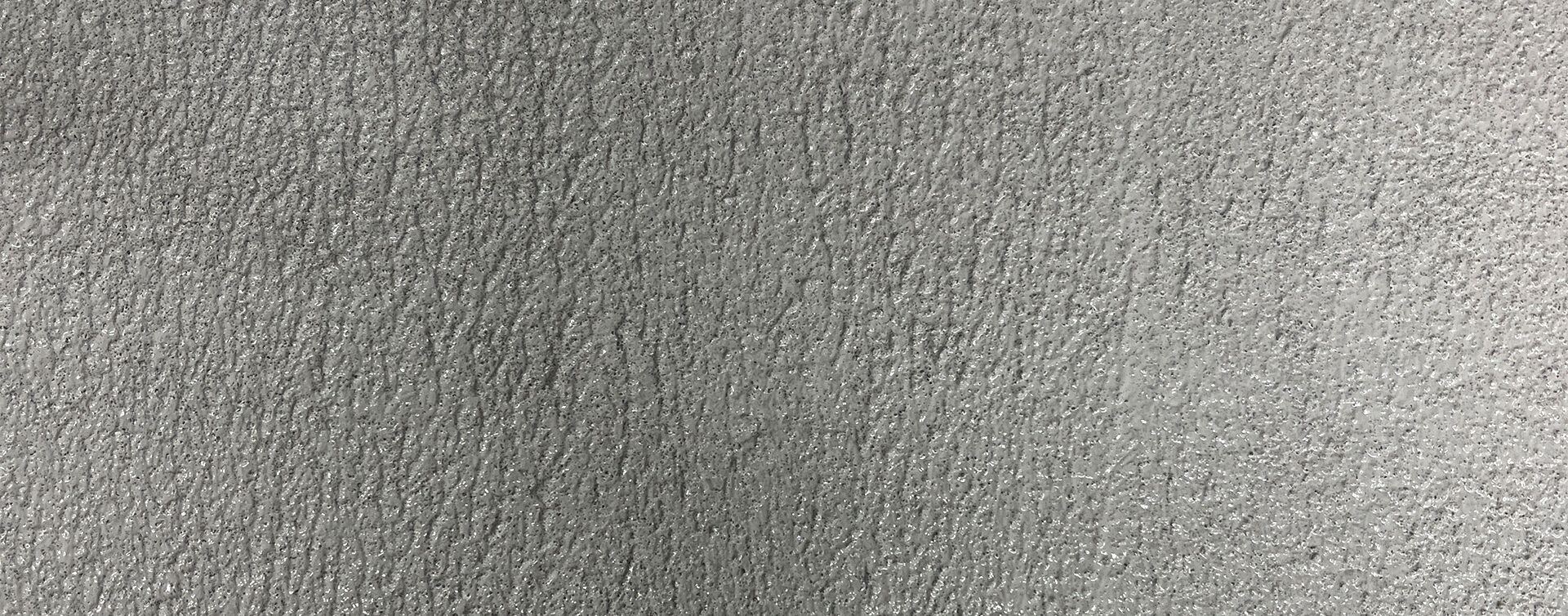

Multigrip is a universal adhesion promoting primer formulated with a blend of water-borne styrene-acrylic resins and graded aggregates. Solvent-free ready-to-use product is suitable for both indoor and outdoor applications, on either horizontal or vertical surfaces. Multigrip can be applied using a roller, regular paint brush or block brush. Applying Multigrip gives a rough, uniform keying surface in colour grey that is ideal for the subsequent application of plaster, render, cementitious adhesives and self-levelling mortars. On highly absorbent surfaces, it reduces and evens out water absorption, so there is no risk of the product not setting properly and drying out too quickly. Once dry, it ensures a strong bond between the layer applied and substrates of various kinds: concrete, lightweight concrete blocks, bricks, stone, plasterboard, gypsum, wood, ceramic, plaster, render, metal etc. The product awarded the EC 1 Plus label by the GEV association for very low emissions of volatile organic compounds.

Preparation

Before applying Multigrip, you must ensure that the substrate is clean, sound and free of all traces of oil, grease, formwork release agents, evaporation retarders or paint. Unsound particles that are not firmly attached to the substrate must be removed thoroughly, along with any grout or cement residue. Do not apply when temperatures are below +5 °C. The temperature must not be allowed to fall below this minimum for the entire duration of the drying period. Do not apply Multigrip if it is foggy or about to rain.

Mixing the product and application

Stir the product until you have a completely even mixture prior to application and apply using a roller, regular paint brush or block brush at a rate of 0,3 – 0,5 kg/m² depending on the substrate’s absorption. Once you have allowed the coat of Multigrip to dry (the minimum time required can range from 30 to 90 minutes depending on environmental conditions and the state of the substrate), you can start applying the subsequent product (plaster, mortar, render, cementitious adhesive, etc.). A dried coat of Multigrip, provided it is clean, can be overcoated even several days after application.

Overcoating times

Before applying the subsequent coat, wait until the Multigrip film is dry. Depending on environmental conditions and substrate absorption, this can range from 30 to 90 minutes. Whatever the case, the dried coat of Multigrip can be overcoated even several days later (Note: on the other hand, if the product applied is exposed for long periods of time to varying atmospheric conditions and stress, this may lead to the material deteriorating and poor performance meaning it does not adequately fulfil the required purpose).

The product is stable for at least 12 months if kept in its original sealed container at temperatures in the +5 °C to +35 °C range.

| Color | Code | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| Grey | 5278 | bucket | 5kg |

72 buckets

|

|

| Grey | 5522 | bucket | 15kg |

33 buckets

|

| PARAMETER AND TEST METHOD | VALUE |

| Colour | Grey |

| Consistency | Creamy liquid |

| Viscosity (MIT 3/C*) | 3 Pa*s |

| Density (ISO 1184-1/B) | 1,49 kg/l |

| Solids content (EN 480-8) | 70 % |

| pH (ISO 4316) | 8 |

| Aggregate particle size (MIT 13*) | 0,5 mm |

| Pull-off strength (EN 1542) | See table** |

* Torggler in-house methods (MIT) are available on request.

** Examples:

| TYPE OF APPLICATION | WITHOUT TORGGLER MULTIGRIP | WITH TORGGLER MULTIGRIP |

| Thixotropic mortar on concrete | 0,8 N/mm² | 1,8 N/mm² |

| Self-levelling mortar on concrete | 1,2 N/mm² | 1,7 N/mm² |

| Self-levelling mortar on ceramic tiles | 0 N/mm² | 0,6 N/mm² |

Coverage with Multigrip ranges from 300 to 500 g/m² depending on the substrate.

Contact our team for personalized support and product guidance.