Mat

Sealing membrane for secure surface sealing in composite structures.

Application areas

Discover more

Sealing membrane for reliable surface sealing in composite structures. EMICODE EC 1 Plus emissions certification.

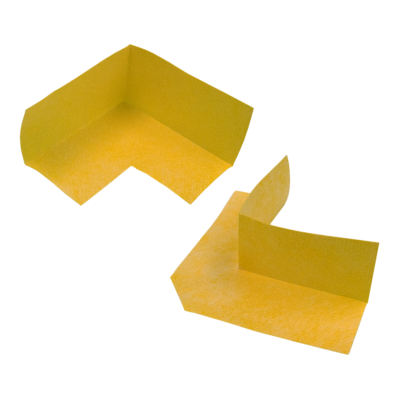

The dry substrate must be clean, stable, ready for covering and have a fine-pored surface. Remove any unevenness such as holes, nests or cracks in a separate preliminary step, e.g. with Multimix Evo or Multifinish. The surface must be level enough to allow the Mat 1000 mm sealing membrane to be laid without any voids. Prime absorbent and non-absorbent substrates with Tile Primer or Multigrip. Before bonding, cut the Mat 1000 mm sealing membrane to size with scissors or a cutter knife. Apply the thin-bed mortar, preferably Tile 250 or Tile 480, evenly to the prepared substrate with a 4-6 mm notched trowel and immediately insert and press down the sealing membrane. Press down and smooth with a trowel from the centre of the membrane towards the edges to ensure that there are no air pockets under the membrane. The membranes should be tightly butted together. When bonding butt joints, use sealing tape 140 mm or, when bonding overlaps, use Flex 2K, Flexistar or Aquatech to bond the entire surface. In the corner area, use sealing tape 140 mm or sealing corner 90° or 270° for inside/outside to seal pipe penetrations and floor drains. Glue the Flex Pipe Collar sealing sleeve over the entire surface and without voids as described above using Flex 2K, Flexistar or Aquatech. If the Mat 1000 mm sealing membrane is used in areas with chemical exposure W2-I and W3-I, the Band 140 mm sealing tape, the overlaps, Corner Tissue 90° or 270° sealing corners inside/outside and the Flex Pipe Collar sealing sleeve are bonded with Flex 2 K in the same way as described above.

Mat 1000 mm – 30 m has no minimum shelf life, but to maintain functionality and performance, it must be stored in a cool, dry and protected environment. However, it is recommended that it be used within 24 months of purchase.

| Code | Dimensions | Packaging size | Pallet | Barcode |

|---|---|---|---|---|

| 15215 | 1000 mm | 30 m |

33 rolls

|

Thin-layer, waterproof and crack-resistant waterproofing membrane for waterproofing walls and floors and for indoor waterproofing in bathrooms, showers, sanitary facilities and areas subject to chemical stress such as large kitchens, canteens, public toilets, etc. The Mat 1000mm-30m waterproofing membrane is approved by the building authorities for composite waterproofing in accordance with DIN 18534 in wet areas with water exposure classes W0-I, W1-I, W2-I, W3-I and with exposure to chemicals in accordance with the ‘test principles for the issuance of a test certificate by the general building authority for sealing materials in combination with tile and slab coverings’.

| Product | Mat 1000 mm – 30 m |

| Description | modified polyethylene with polypropylene fleece on both sides |

| total thickness | approx. 0,62 mm |

| weight | approx. 275 g/m2 |

| Operating temperature min./max. | -30°C / +90°C |

| burst pressure | 3 bar |

| Breaking load in longitudinal direction DIN 527-3 | 370 N / 50 mm |

| Lateral breaking load DIN 527-3 | 250 N / 50 mm |

| Elongation at break in longitudinal direction DIN 527-3 | 90% |

| Lateral elongation at break DIN 527-3 | 120% |

| Water pressure resistance (1.5 bar) DIN EN 1928 | > 1,5 bar |

| SD value DIN EN 1931 | > 85 m |

| Fire behaviour DIN EN 4102 | B 2 |

| UV resistance DIN EN ISO 4892-2 | < 450 h |

| Resistance after 7 days of storage in the following chemical substances at room temperature | |

| Hydrochloric acid at 3% | Consistent |

| Sulphuric acid at 35% | Consistent |

| Citric acid at 100 g/l | Consistent |

| Lactic acid at 5% | Consistent |

| Potassium hydroxide at 3% / 20% | Consistent |

| Sodium hypochlorite at 0.3 g/l | Consistent |

| Salt water (20g/l sea salt water) | Consistent |

Contact our team for personalized support and product guidance.