Black Hydro Pittura

Solvent-based protective and decorative paint, based on bitumen, aluminium paste, selected synthetic resins and special additives.

Solvent-based protective and decorative paint, based on bitumen, aluminium paste, selected synthetic resins and special additives.

Discover more

Stir the product before application. Apply Black Hydro Paint with a brush, scrub brush, roller or airless spray (it can be diluted with nitro thinner or common solvent-based bituminous primers). It is important that the paint is applied in a single direction, as application in different directions alters the ‘leafing’ of the aluminium paste. Bitumen polymer membranes finished on the surface with synthetic non-woven fabric can be painted immediately, but more than two coats must be applied in order to achieve sufficient coverage. Use common synthetic thinners to clean tools.

If stored in a dry, cool environment in its original sealed packaging, the product will keep for at least 24 months.

On new bituminous surfaces, carry out a preliminary application test to verify the correct compatibility of the product with the substrate. However, we recommend waiting a few months after installing the new membrane to allow for the complete elimination of any bituminous hydrocarbons that may have surfaced. Do not apply to very hot substrates, as this would have a negative effect on the cohesion and adhesion of the product to the substrate. Store in the original packaging, tightly closed. Flammable product. Do not expose to temperatures >40 °C, heat sources, open flames or other sources of ignition. Follow the information on the safety data sheet.

| Color | Code | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| Aluminium | 8171 | bucket | 20 l |

33 buckets

|

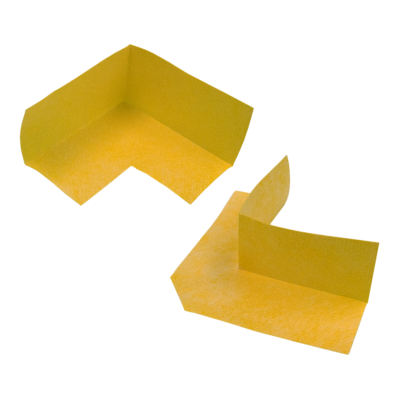

It is used as a protective coating for exposed bitumen-polymer membranes applied either cold or hot, giving them a shiny silver appearance. It is suitable for painting smooth bitumen-polymer membranes placed on insulation packages. Suitable for metal structures of sheet metal roofs, gutters, flashings, metal boxes, tanks, chimneys and on ferrous and galvanised substrates in general.

| PARAMETERS | VALUES |

| Appearance | Liquid |

| Colour | Aluminium |

| Dry residue (m/m at 130 °C) according to UNI EN ISO 3251 | (52÷58)% |

| Viscosity (Flow time at 20°C, cup Φ 4 mm) according to DIN 53211 | 22 ÷ 30 seconds |

| Density (at 20°C) according to UNI EN ISO 2811-1 | (1,04÷1,10)kg/l |

| Drying time | 100÷120 minutes* |

| Closed cup flash point according to ASTM D3828-87 | > +23°C |

* Values recorded at a temperature of 23°C and humidity of 50%. The data provided may vary depending on the thickness of the product applied and the specific conditions on site: temperature, humidity, ventilation, absorbency of the substrate.

Overall consumption varies from 300 to 400 grams/m². Two coats are recommended; apply the second coat when the first is completely dry.

Contact our team for personalized support and product guidance.