CA Poly

Two-component polyester resin-based chemical anchor without styrene for fixing medium-light loads on un-cracked concrete, solid and perforated brick masonry and autoclaved cell concrete.

Two-component polyester resin-based chemical anchor without styrene for fixing medium-light loads on un-cracked concrete, solid and perforated brick masonry and autoclaved cell concrete.

Combined with threaded rods, it is used in many construction site applications for fixing elements of medium weight, connected to light carpentry, where there is the need for rapid commissioning without creating tension in the substrate: installation of shading elements, shutters, windows, doors, air conditioners, fences, antennas, alarm systems, lighting fixtures, advertising signs. Thanks to its styrene-free chemistry it can be used in closed environments as well. The product is approved for fixings with anchorage depths ranging from 6 to 32 cm thereby allowing for a highly flexible use, up to twenty times the diameter of the threaded rod.

The temperatures of the substrate during installation range from 0 to +30 °C.

The certified operating temperatures are within the ranges:

Discover more

Two-component polyester resin-based chemical anchor without styrene for fixing medium-light loads on un-cracked concrete, solid and perforated brick masonry and autoclaved cell concrete. It can be used in combination with threaded rods in common carpentry, where there is a need for quick commissioning.

Store between +5 and +30 °C, away from UV rays. When stored in a dry and covered place in its original sealed packaging CA Poly is stable for at least 12 months.

Do not use the product:

| Code | Bicomponent | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| 8047 | 2 components | cartridge | 12x300 ml |

72 cardboards

|

|

| 8048 | 2 components | cartridge | 12x400 ml |

52 cardboards

|

Combined with threaded rods, it is used in many construction site applications for fixing elements of medium weight, connected to light carpentry, where there is the need for rapid commissioning without creating tension in the substrate: installation of shading elements, shutters, windows, doors, air conditioners, fences, antennas, alarm systems, lighting fixtures, advertising signs. Thanks to its styrene-free chemistry it can be used in closed environments as well. The product is approved for fixings with anchorage depths ranging from 6 to 32 cm thereby allowing for a highly flexible use, up to twenty times the diameter of the threaded rod.

The temperatures of the substrate during installation range from 0 to +30 °C.

The certified operating temperatures are within the ranges:

| Fixing of min 5 µ grade 5.8 galvanized steel threaded rods on concrete C20/25 | ||||||||

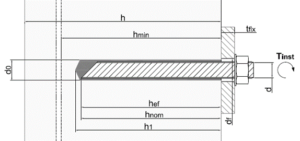

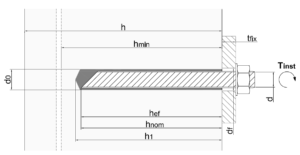

| Characteristic dimensions | M8 | M10 | M12 | M16 | M20* | M24* | ||

| d0 | Hole diameter | [mm] | 10 | 12 | 14 | 18 | 24 | 28 |

| h1 | Hole depth | [mm] | 85 | 95 | 115 | 130 | 175 | 215 |

| hnom | Nominal anchoring depth | [mm] | 80 | 90 | 110 | 125 | 170 | 210 |

| hmin | Minimum thickness of base material | [mm] | 115 | 120 | 140 | 161 | 218 | 266 |

| Tinst | Tightening torque | [Nm] | 10 | 25 | 45 | 90 | 150 | 200 |

| scr,N | Hole centre distance | [mm] | 240 | 270 | 330 | 375 | 510 | 630 |

| ccr,N | Distance from edge – traction | [mm] | 120 | 135 | 165 | 168 | 255 | 315 |

| Smin | Minimum hole centre distance | [mm] | 40 | 50 | 60 | 75 | 100 | 115 |

| Cmin | Minimum distance from the edge | [mm] | 40 | 50 | 60 | 75 | 100 | 115 |

| Sw | Key | [mm] | 13 | 17 | 19 | 24 | 30 | 36 |

| df | hole Ø in the object to be fixed | [mm] | 9 | 12 | 14 | 18 | 22 | 26 |

*Diameters M20 and M24 are not subject to CE marking.

| RECOMMENDED LOADS | |||||||

| Global safety factor applied | |||||||

| Fixing on non-cracked concrete C20/25 with grade 5.8 threaded rods | |||||||

| M8 | M10 | M12 | M16 | M20 | M24 | ||

| Traction | [kN] | 9.0 | 14.0 | 18.4 | 23.3 | 29.6 | 38.7 |

| Shear | [kN] | 5.4 | 8.6 | 12.5 | 23.3 | 36.2 | 52.5 |

– Loads valid for operating temperatures ranging from -40°C to +40°C

– Loads per single anchoring agent irrespective of hole centre distance, edge distance and concrete thickness ≥ 2hef

– Shear action not directed towards the edge

| Fixing on solid brick and compact masonry | ||||||

| Rod cl 4.8 | Hole diameter | Hole depth | Fixable Thickness | Tightening | Recommended traction | Recommended shear |

| M8 x 100 | 10 mm | 85 mm | 10 mm | 7 Nm | 2.0 kN | 3.0 kN |

| M10 x 115 | 12 mm | 90 mm | 20 mm | 15 Nm | 2.6 kN | 3.4 kN |

| M12 x 130 | 14 mm | 100 mm | 30 mm | 25 Nm | 2.8 kN | 3.9 kN |

| Fixing on hollow brick with cage | ||||||

| Rod cl 4.8 | Hole diameter | Hole depth | Fixable Thickness | Tightening | Recommended traction | Recommended shear |

| M8 x 100 | 16 mm | 90 mm | 10 mm | 5.0 Nm | 0.9 kN | 2.0 kN |

| M10 x 115 | 16 mm | 90 mm | 20 mm | 7.5 Nm | 0.9 kN | 2.0 kN |

| M12 x 130 | 16 mm | 90 mm | 30 mm | 10.0 Nm | 0.9 kN | 2.5 kN |

The recommended load data refer to applications on materials with medium mechanical properties. Given the variety of masonry substrates, for applications on substrates different from those considered, the load values must be obtained by means of appropriate on site tests.

| Type and diameter of rod | Hole diameter (mm) | Anchoring hole depth (mm) | Number of fixings (300 ml) | Number of fixings (400 ml) | |

| Threaded rods | M8 | 10 | 85 | ± 60.5 | ± 81 |

| M10 | 12 | 95 | ± 37.5 | ± 50.5 | |

| M12 | 14 | 115 | ± 23 | ± 30.5 | |

| M14 | 16 | 115 | ± 17 | ± 22.5 | |

| M16 | 18 | 130 | ± 12 | ± 16.5 | |

| M18 | 20 | 130 | ± 8.5 | ± 11 | |

| M20 | 24 | 175 | ± 5 | ± 7 | |

| M22 | 26 | 190 | ± 4 | ± 5 | |

| M24 | 28 | 215 | ± 3 | ± 4 | |

| M27 | 30 | 245 | ± 2.5 | ± 3 | |

| M30 | 35 | 275 | ± 1.5 | ± 2 | |

| M33 | 37 | 300 | ± 1 | ± 1.5 | |

| M36 | 40 | 300 | ± 1 | ± 1.5 | |

| M39 | 42 | 360 | ± 1 | ± 1 | |

| Improved adhesion rods | Ø 8 | 12 | 80 | ± 42 | ± 56 |

| Ø 10 | 14 | 100 | ± 25 | ± 33.5 | |

| Ø 12 | 16 | 120 | ± 16 | ± 21.5 | |

| Ø 14 | 18 | 140 | ± 11 | ± 14.5 | |

| Ø 16 | 20 | 160 | ± 8 | ± 10.5 | |

| Ø 18 | 22 | 180 | ± 6 | ± 7.5 | |

| Ø 20 | 25 | 200 | ± 4 | ± 5.5 | |

| Ø 22 | 26 | 220 | ± 3.5 | ± 4.5 | |

| Ø 24 | 28 | 240 | ± 2.5 | ± 3.5 | |

| Ø 25 | 30 | 250 | ± 2 | ± 3 | |

| Ø 26 | 32 | 260 | ± 2 | ± 2.5 | |

| Ø 28 | 34 | 280 | ± 1.5 | ± 2 | |

| Ø 30 | 37 | 300 | ± 1 | ± 1.5 | |

| Ø 32 | 40 | 320 | ± 1 | ± 1.5 | |

| Fixings with cages in hollow bricks | M8 | 12 | 50 | ± 38.5 | ± 51.5 |

| M8 | 12 | 60 | ± 32.5 | ± 43.5 | |

| M8 | 12 | 80 | ± 25 | ± 33.5 | |

| M10 | 16 | 85 | ± 13.5 | ± 17.5 | |

| M10 | 16 | 100 | ± 11.5 | ± 15 | |

| M10 | 16 | 135 | ± 8.5 | ± 11.5 | |

| M10 | 16 | 140 | ± 8 | ± 11 | |

| M14 | 17 | 130 | ± 8 | ± 10.4 | |

| M12 | 20 | 85 | ± 8.5 | ± 11.5 | |

| M16 | 22 | 150 | ± 4 | ± 5.5 | |

| M16 | 22 | 200 | ± 3 | ± 4 | |

| M20 | 30 | 250 | ± 1.5 | ± 2 | |

The number of specified fixings derives from the calculation of the theoretical volume of product needed to fill the holes, excluding the volume of the rod: although a certain amount of waste has been taken into account, the real quantity of product may vary depending on the installation method.

Contact our team for personalized support and product guidance.