Tile 480 is a grey or white cementitious adhesive highly-resistant powder adhesive, based on cement, graded aggregates, a high percentage of synthetic resins and specific additives, specially formulated for laying large-sized porcelain and glazed stoneware as well as ceramic tiles and natural stone of all types and sizes, as long as these are resistant to water, staining and deformation, even on substrates subject to movement. After mixing with water, you have an adhesive which is easy to use, highly thixotropic and highly flexible and adhesive for all types of surface and also on old floors and ceramic surfaces. When applied on walls, it does not run and prevents wall tiles from slipping. Thanks to its long open time, laying tiles is easy even in warm, windy climates. The deformability of the hardened product permits absorption of the movements of the substrate, making it ideal for flooring subject to high stress. It resists freezing/thawing cycles. Tile 480 is classified as a cementitious adhesive of class C2 TE S1 according to EN 12004.

Instructions for use

Preparation

The surfaces to be covered must be suitably dry, resistant, solid and regular, free of oils and greases, dust, loose material, dirt of any kind and any traces of old paint. The surfaces must also be sufficiently cured and free of significant shrinkage. As a general rule, traditional cement bedding with normal setting and hardening must be cured for at least 28 days. Cement or cement lime plasters must be dried for at least 14 days. Major surface imperfections and irregularities such as level differences, cavities and gravel pockets with a depth greater than 20 mm must be filled out with a self-levelling smoothing product such as Livellina 5-30 or special mortars for walls such as ACS Rinnova or ACS Restauro. Very porous, flaking or dusting surfaces with poor mechanical strength must be treated in advance with Tile Primer.

Mixing the product

Mix Tile 480 with 29-31% clean water (7.25-7.75 litres per 25 kg bag) as follows: pour almost all the mixing water required in a suitable container. Then add the powder product, slowly, and mix at the same time using a low speed electrical drill with mixer attachment. Once you have added all the powder product, pour in the rest of the water and mix until the product is smooth and lump-free, with a semi-fluid consistency. Make sure you remove all non-mixed lumps of material from the walls and the bottom of the container. Allow the mixture to stand for about 5 minutes and then mix again briefly. The adhesive mix prepared in this way has a pot life in the container of about 5 hours under normal conditions (at 20°C). Higher temperatures reduce the pot life, lower temperatures increase it.

Application

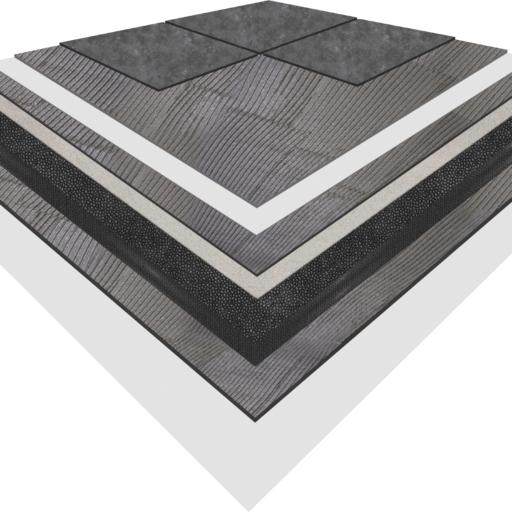

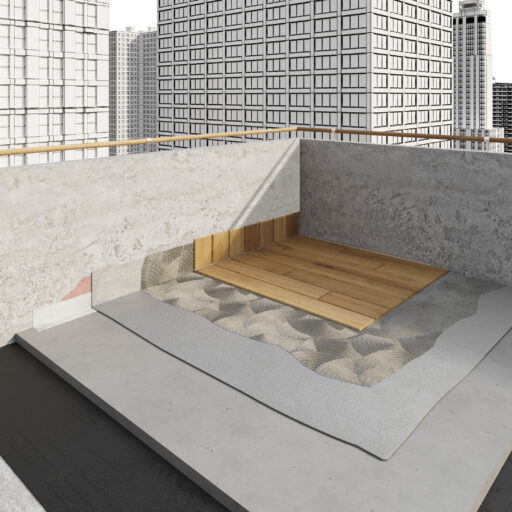

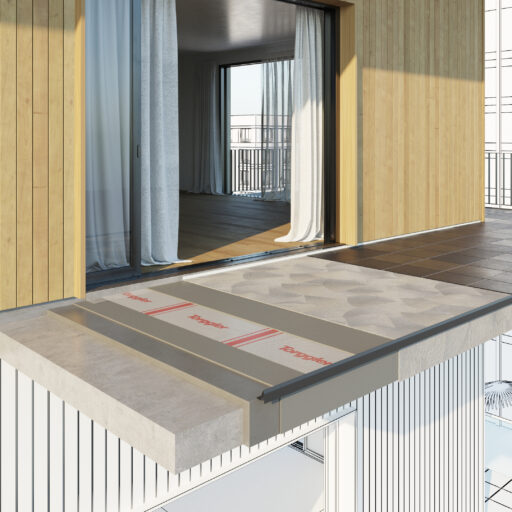

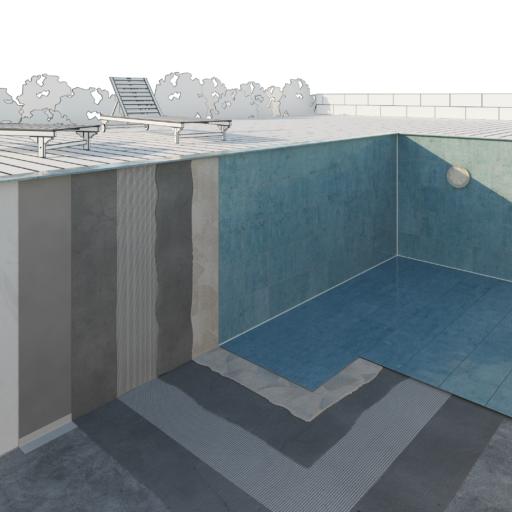

If subject to direct sunlight, that is, high temperatures, wet the surface with a sponge to cool it and then wait until all the surface water has evaporated. Apply the adhesive with an appropriate toothed trowel. The size of the trowel teeth depends on the type and size of the tile to be glued: total coverage of the back of the tiles must be guaranteed. For better adhesion, first apply a thin and uniform layer of adhesive on the surface using the smooth part of the toothed trowel and then apply, immediately, a second layer of the thickness required using the toothed part of the trowel. Apply the tiles, pressing them slightly and moving them crossways slightly. When gluing tiles with marked relief pattern on the back, for outdoor applications, especially in areas subject to major heat changes or freezing/thawing cycles, for laying on heated floors and flooring subject to high levels of stress, for tank and swimming pool applications and for laying large tiles (more than 33×33 cm), follow the “buttering-floating” technique: that is to say, apply the mixed adhesive with the toothed trowel to the surface and spread it out using a trowel on the back of the tile, smoothing off as required. Provided the quantity of adhesive spread out is sufficient, you now have adhesive-tile contact extended along the entire gluing surface (this condition is essential for laying floors and surfaces exposed to freezing cycles and considerable stress from water). Mix with one part Antol Flex and one part water for vitreous mosaic tiling and applications in tanks and swimming pools. Only lay the tiles within the time interval during which the adhesive spread out is still fresh and sticky, that is, before a surface film forms. This time interval is known as the “open time” of the adhesive and depends on the environmental conditions. The open time of Tile 480 is longer than 30 minutes at 23 °C and 50% relative humidity. High temperatures and conditions of direct sunlight and wind or very porous and absorbent surfaces may reduce the open time considerably. Low temperatures, high environmental humidity and non-absorbent surfaces may increase the open time. If the open time has passed and the adhesive spread out has formed a surface film, you must use the toothed trowel again to break the film and “freshen up” the surface. Do not wet the surface as this would create a film of anti-adhesive water which would prevent contact of the tiles with the adhesive and the entire operation would be compromised definitively. The tiles do not normally require wetting before laying. However, tiles with dusty back should be cleaned by dipping them in clean water for a few seconds. For gypsum or anhydrite surfaces, pre-treatment with Tile Primer is required.

Cleaning

The tools used for laying may be cleaned with water before the adhesive hardens. Once the adhesive has hardened, you may only clean them using mechanical instruments. Any dirt on the surface of the tiles must be cleaned before the adhesive hardens using a damp cloth.