Aquaproof

Fine waterproofing mortar.

Application areas

Discover more

Aquaproof is a grey, ready-to-use single component cement mortar. The product is made from very resistant cements, selected fine grain aggregates, special synthetic resins and organic additives. Special resins, latest generation water repellent agents, filler compounds and optimum aggregate grain size ensure excellent waterproofing even with thin coats. Excellent workability and ease of application using various methods (paddle, small brush, roller, large brush, spray). Excellent adherence to the substrate, very good water retention, deep filling of support capillaries thanks to osmotic penetration followed by swelling.

Preparation for prose

Substrates must be non-shedding, solid and regular but sufficiently roughened, hexane clean, free of oil and grease, dust, friable material and dirt in general, and without residues of paint films, and must be properly cured and free of significant shrinkage. In the case of efflorescence these must be carefully removed on the surface by mechanical cleaning and then neutralized in depth with Antisal treatment. Surface imperfections and irregularities, such as gravel nests, eroded or deteriorated spots, and holes in reinforcing formwork spacers, must be repaired beforehand and equalized with a suitable mortar, for example Umafix or Rinnova. Floor-wall joints should be concave (“shelled”) in shape. Wet the surface to be waterproofed until completely saturated and allow excess water to evaporate or remove it with a sponge, taking care to remove any surface water film.

Product preparation

For the first coat (primer) to be applied always with a brush, mix Aquaproof with 25-27% clean water (equal to 6.25-6.75 liters per 25-kg bag) using a mechanical stirrer (low-speed drill with special propeller) until the mixture is homogeneous and free of lumps. Let it rest for about 10 minutes, then stir briefly and if necessary correct the consistency with a small addition of water. To achieve good anchorage on substrates previously treated with Antisale, mix the first coat of Aquaproof with about 25 to 26 percent (equal to 6.25 to 6.5 liters per 25-kg bag) of a 1:3 solution of Neoplast Latex diluted 1:3 (1 p.v. of Neoplast Latex with 3 p.v. of water). On old substrates where it may be difficult for Aquaproof to adhere, mix the first coat with about 27-28% (equal to 6.75-7.0 liters per 25 kg bag) of a 1:2 diluted solution of Neoplast Latex (1 p.v. of Neoplast Latex with 2 p.v. of water).

Laying instructions

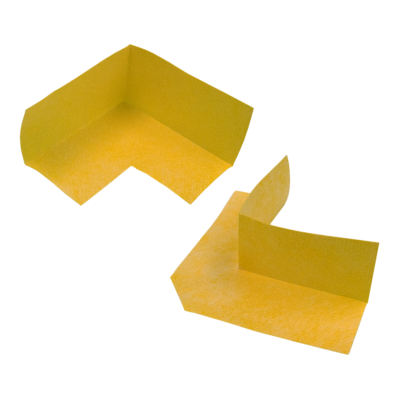

Apply the Aquaproof mix by brush, taking special care to evenly cover any irregularities and fill surface porosity; special care should be taken in the case of corners, edges, shells and floor-wall joints. If subsequent coats are to be applied by trowel, mix Aquaproof with 23 to 25 percent clean water (equal to 5.75 to 6.25 liters per 25-kg bag) using the same procedure adopted for preparing the mix to be applied by brush. In all cases the mix prepared in this way remains workable for about 40 minutes under normal conditions (at 20 °C); in the case of higher temperatures the workability time is shortened, in the case of lower temperatures the workability time is lengthened. Subsequent coats, if applied by brush, should be crisscrossed from the previous coat. For roller and brush applications, there is no need to apply the first coat by brush, and the same dosage of mixing water adopted for brush application can be used. For spray applications, there is no need to apply the first coat by brush, and indicatively the same mixing water adopted for brush, roller and brush application can be used, but it is necessary for the product to be mixed separately with water, allowed to rest for the right amount of time as described above, then poured into the feed hopper of the plastering machine. If necessary, adjust the mixing water dosage according to the type of plastering machine and type of nozzle used. Apply by coat, either by trowel or by brush, roller, mop and spray, thicknesses up to 1 mm, waiting until the underlying coat has hardened sufficiently before applying the next one. Do not exceed this thickness to avoid the danger of cracking. In the case of moisture and oozing, apply at least 2 coats. In the case of groundwater and standing water, water under positive pressure and water under negative pressure apply at least 3 coats. The waiting time between coats can vary significantly depending on the porosity of the substrate and environmental conditions. Generally, it is sufficient to wait 4-6 hours between coats. In the case of high temperatures and/or strong ventilation, to avoid too rapid evaporation of the mixing water keep the surface moist by spraying water mist. If necessary, the last applied coat can be finished with sponge trowel like a normal smoothing mortar. If Aquaproof is to come in contact with very soft water (0 to 10 degrees French hardness) consult the Technical Office. Tools used for installation can be cleaned with water before the mortar hardens; thereafter cleaning can be done only by mechanical removal.

Aquaproof must be stored in a dry place. Unopened in its original bags, the product can be stored for at least 12 months.

| Color | Code | Packaging | Packaging size | Pallet | Barcode |

|---|---|---|---|---|---|

| Grey | 6360 | bag | 25kg |

50 bags

|

| PARAMETER AND TEST METHOD | VALUE |

| MEASURED ON POWDER PRODUCT | |

| Colour | grey |

| Consistency | powder |

| Apparent density (sec. EN 2811-1) | 1290 kg/m3 |

| Grain size (sec. EN 12192-1) | 0 – 0,5 mm |

| Chloride content (sec. EN 1015-17) | 0,05% |

| Termogravimetria (perdita di massa a 600 °C sec. EN 11358) | 3,2% |

| Ash content (sec. EN 3451-1) | 96,4% |

| MEASURED ON FRESH MIX | |

| Mixing water: roller and brush application | 23 – 25% ( 5,75 – 6,25 litres per 25 kg bag (paddle) |

| Mixing water: trowel application | 25 – 27% (6,25 – 6,75 litres per 25 kg bag) (brush, roller, large brush, spray) |

| Mixture consistency | Plastic workable with trowel or fluid |

| mixture pH | > 12 |

| Mixture density (sec. EN 1015-6) | 1.910 kg/m3 |

| Air content (sec. EN 1015-7) | 9% |

| Bleeding (sec. DIN 4227/5) | <1% |

| Setting times (sec. EN 1015-3) | 210 mm |

| Setting times (sec. EN 196-3): Start of setting | 4 – 5 hours |

| Setting times (sec. EN 196-3): End of setting | 7 – 8 hours |

| Mixture workability time | approx. 40 minutes under normal conditions (a +20 °C) |

| Waiting time for setting between coats | from 4 a 6 hours depending on the porosity of the substrate and environmental conditions. |

| Full curing time | 28 days |

| Application temperature | from +5 °C to +30 °C |

| HARDENED PRODUCT VARIATIONS |

|

| Operatig temperaure | from -20 °C to +90 °C |

| Waterproofing(sec. DIN 1048): 28 days at 1.5 bar of positive hydrostatic pressure | resist |

| Waterproofing(sec. DIN 1048): maximum load under positive hydrostatic pressure | 3,0 bar |

| Waterproofing(sec. DIN 1048): maximum load under negative hydrostatic pressure | 0,5 bar |

| Compression strength after 28 days (according EN 196-1) | 28 N/mm2 |

| Bending strength after 28 days (according EN 193-1) | 6,0 N/mm2 |

| Water shrinkage after 90 days (according to IBH Directives) | 1,7 mm/m |

| Capillary absorption coefficient – μ (according DIN 52615) | 90 |

| Consumption | from 2,0 to 6,0 kg/m2 |

| Max attainable thickness | 1 mm per coat (up to 4 mm in total) |

| DETERMINATIONS ON HARDENED PRODUCT ACCORDING TO EN 1504-2 | |

| Water vapour permeability (according EN 7783) | SD = 0,19 m (thickness 2,5 mm) |

| Liquid water transmission rate (according EN 1062-3) | w = 0,03 kg/(m2*h0,5) |

| Direct traction adhesion force (according EN 1542-1) | 1,7 MPa (on dry concrete) |

| Direct traction adhesion force (according EN 1542-1) | 1,4 MPa (on wet concrete) |

The consumption of Aquaproof is approximately 1.6 Kg/m2 per mm of thickness.

The total needed depends on the waterproofing requirements of the structure being treated.

For small brush, roller, large brush and spray applications: 1-1.2 Kg/m2 per coat

For paddle applications: approximately 1.5 Kg/m2 per coat

Minimum consumption:

Contact our team for personalized support and product guidance.