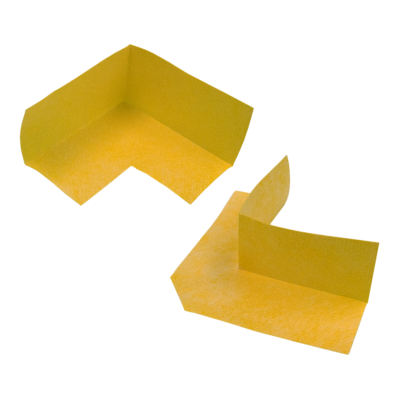

Corner Tissue 270°

Reinforcement tissue for open corners.

Application areas

Discover more

Reinforcement tissue for open corners.

Apply a layer of liquid waterproofing product such as Aquatech, Flex 2K or cementitious adhesives such as Tile 250 or Tile 480 to the corners to be waterproofed with Corner Tissue 270°, using a notched trowel of 3 -4 mm, making sure the tape adheres well to the waterproofing product applied, without creating folds or bubbles and taking care to ensure that material flows out of the side perforations. Joints between waterproofing accessories and/or PP Tape must be overlapped by at least 5 cm and bonded with the chosen liquid waterproofing product or adhesive. Once PP Tape has been applied to all joints, the chosen waterproofing system can then be installed. This waterproofing should be applied continuously over PP Tape. All Torggler products suitable for standardised processing are listed in the “Test Certificates”.

Corner Tissue 270° has no expiration but should be stored in a cool, dry and sheltered place to preserve its integrity and performance characteristics. However, it is recommended to be used within 24 months of purchase.

| Code | Packaging size | Pallet | Barcode |

|---|---|---|---|

| 15210 | 25 piece |

250 pieces

|

Corner Tissue 270° for flexible sealing of corners, joints and fittings in combination with liquid waterproofers and membranes.

| Parameter | Value |

| Description | corner covered with non-woven polypropylene fabric on both sides |

| Material composition | Substrate: PP Coating : weather-resistant thermoplastic elastomer |

| Colour | grey |

| Total thickness | approx. 0,66 mm |

| Material weight | approx. 364 g/m² |

| Temperature resistance: min./max | -30 °C / +90 °C |

| PHYSICAL PROPERTIES | |

| Burst pressure | 2 bar |

| Longitudinal breaking load DIN 527-3 | 120 N / 15 mm |

| Lateral breaking load DIN 527-3 | 25 N / 15 mm |

| Longitudinal extension at break DIN 527-3 | 70 % |

| Lateral extension at break DIN 527-3 | 300 % |

| Resistance to water pressure (1,5 bar) DIN EN 1928 | > 1,5 bar |

| Value SD DIN EN 1931 | 16 m |

| UV resistance DIN EN ISO 4892-2 | < 500 h |

| CHEMICAL PROPERTIES: Resistance after 7 days immersion in the following chemical agents at room temperature |

|

| 3% Hydrochloric Acid | resistant |

| 35% Sulphuric Acid | resistant |

| Citric acid 100 g/l | resistant |

| Lactic Acid 5% | resistant |

| 3% / 20% Potassium Hydroxide | resistant |

| Sodium Hypochlorite 0,3 g/l | resistant |

| Salt water (20 g/l Sea salt water) | resistant |

Contact our team for personalized support and product guidance.