Flex 2K

Two-component, flexible, fibre-reinforced, waterproofing cementbased mortar, which can be reinforced with fibreglass mesh, for flexible waterproofing and protective smoothing of cementitious substrates. Good UV resistance, elastic to -20 °C.

Two-component, flexible, fibre-reinforced, waterproofing cementbased mortar, which can be reinforced with fibreglass mesh, for flexible waterproofing and protective smoothing of cementitious substrates. Good UV resistance, elastic to -20 °C.

Application areas

Discover more

Flex 2K is a two-component cement-based mortar. Component A is a mixture based on cement, selected fine-grained aggregates, fibres and specific additives. Component B is a mixture of highly flexible acrylic polymers in water dispersion. Once the two components have been mixed, a mixture having excellent workability is obtained, easily applied with a construction trowel, even vertically without dripping and scraps, with excellent adhesion to the substrate. It is resistant to frost-thaw cycles and thawing salts, and has excellent resistance to the spread of CO2. It keeps excellent elasticity even at low temperatures. Flex 2K is a liquid-applied waterproofing product to be used under ceramic tiles bonded with adhesives according to EN 14891 classified as type CM O2 P and is a surface protection coating according to EN 1504-2 type C and class PI, MC, IR according to EN 1504-9. Once installed, the product meets the requirements for class E construction materials according to DIN EN 13501-1.

Preparation for installation

Substrates must be damp, solid and regular but sufficiently roughened, clean and sound, free of oil and grease, dust, crumbly material and dirt in general, and free of residues of paint film, and must be suitably cured and free of significant shrinkage. In case of efflorescence these must be carefully removed on the surface by mechanical cleaning. Imperfections and surface irregularities such as gravel nests, eroded or deteriorated points, spacer holes in the reinforcement formworks, must be repaired beforehand and evened out with a suitable mortar, e.g. Umafix, Rinnova or Monorasante. Where possible, round off the floor-wall connections in a concave (“shell”) shape. Lightly moisten the surface to be waterproofed, taking care to remove any film of surface water with a dry sponge.

Product preparation

Mix Flex 2K component A (powder) with component B (liquid) using one complete tank of component B (8.5 kg) for each bag of component A (25 kg). It is recommended to prepare the mixture in the following way: in a special container pour all the component B (liquid), then pour the component A (powder) slowly stirring the mixture with a mechanical stirrer (low-speed drill with a specific propeller). Once all the powder has been poured, stir until the mixture is homogeneous and free of lumps, taking particular care to remove lumps of unmixed material from the walls and bottom of the container. The mix thus prepared remains workable for about 1 hour under normal conditions (at +20 °C). At higher temperatures the workability time is shorter, at lower temperatures the workability time is longer.

Istruction for installation

Apply the product in two coats with an American trowel, in a maximum thickness of 2 mm each coat, waiting between one coat and the other long enough to allow the previous coat to harden (about 4-6 hours at +20 °C). In the case of application on micro-cracked substrates, and in cases where microcracks may occur due to settling movements of the structure, it is advisable to always bury a square reinforcement mesh in glass or synthetic fibre between the first and second coat, provided it is alkaliresistant and has a weight of not less than 150 g/m2. In the presence of pre-existing perimeter joints, expansion joints or connection joints, apply the appropriate coats of Flex 2K till the edges and first millimetres of the sides of the joint, avoiding clogging, possibly with the help of a polystyrene and/or polyurethane strip. After sufficient hardening of the last coat of the waterproofer, remove the strip, clean and remove the residues, if any, from the joint and then seal it, after filling the gaps, with Low Modulus Silicone. It is advisable and, in cases of highly stressed joints and/or in situations where adhesion may be critical, it is necessary to primer the sides of the joint with Silicone Primer, before applying the sealant, in order to guarantee maximum performance in terms of mechanical seal and waterproofing of the system. Particular attention must be paid to waterproofing at corners and/or floor-wall connections if these, even in the absence of expansion joints, are characterised by a certain mobility. In this case, before applying the various coats of Flex 2K, it is necessary to install Self-adhesive Perimeter Tape on top and along the line at the connection. The area adjacent to the connecting line must be sufficiently regular and uniform to ensure adequate positioning and correct adhesion of the self-adhesive tape; if this is not possible, the area should first be regularised with other mortars and/or skimming such as Rinnova, Monorasante, Multifinish and other mortars and/or skimming from the Torggler range, opting for the most suitable product according to the nature and condition of the substrate, the level of irregularity and the mechanical resistance guaranteed by it. The surface waterproofed with Flex 2K, while having good mechanical resistance, is not suitable to withstand the continuous traffic of people and vehicles and its impact resistance is limited, so if it is to be walked on, it must be suitably protected with a ceramic coating or other protective flooring. On the surface waterproofed with Flex 2K and hardened for at least 7 days, ceramic floor and/or wall tiles can be bonded with adhesives from the Torggler range such as Tile 900, Tile 700, Tile 480, Tile 350, Tile 250 or T 250 and T 480. When installing ceramic floor and wall tiles, respect pre-existing expansion joints. In case of doubt about the most appropriate type of adhesive, contact the Technical Department of Torggler S.r.l, as in the case of subsequent processing.

Cleaning

The tools used for laying can be cleaned with water before the mortar hardens; afterwards cleaning can be carried out only by mechanical removal.

EXAMPLES OF APPLICATIONS

Adhesive liquid waterproofing (according to AIV-F “Verbundabdichtungen”)

1. Wall and floor surfaces according to DIN 18534 (interior waterproofing) in water exposure classes W0-I to W3-I (without chemical exposure).

2. Floor surfaces in accordance with DIN 18531 Part 5 (sealing of balconies, loggias and porches).

3. Wall and floor surfaces in accordance with DIN 18535 Part 5 (sealing of containers and basins), treated with waterproofing products to be applied in liquid form in combination with AIV-F tiles.

Types of substrates

Depending on the moisture stress classes or type of substrate, mineral substrates made of concrete, lightweight concrete, aerated concrete, cement and lime and cement based plasters, gypsum plaster and gypsum fibreboard, gypsum plaster and wall binding agent, solid joint masonry, also masonry (nonmixed masonry) are suitable. For cement screeds, calcium sulphate screeds (anhydrite and anhydrite sliding screeds), dry screeds, cement-bonded dry construction panels, metal substrates (for treatment of metal substrates) contact our Technical Assistance Service. The “General Building Authority Test Certificates” according to PG-MDS and PG-AIV-F issued by the Materialprüfanstalt für das Bauwesen TU Braunschweig are available.

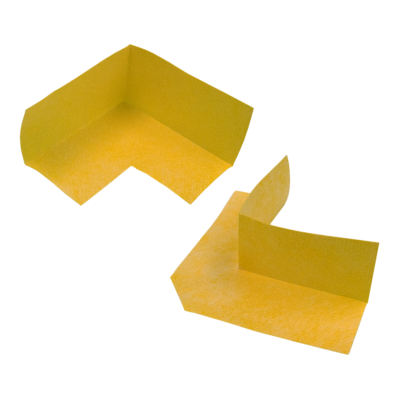

System description / AIV-F processing

The substrate must be pre-treated with Tile Primer (acrylic styrene polymer based primer in water dispersion) or Multigrip (one-component adhesion promoter), applied in one coat with roller or brush. Install the various accessories such as through-hoses with Flex Pipe Collars 22-37, 50-75 and 93-146, the polypropylene reinforcement tape with side perforations – transversely extendible and longitudinally stable, type PP Tape 120 MM-50, the Corner Tissue 90° and the Corner Tissue 270°, with products from the Torggler range such as Tile 250 (white or grey) or Tile 480 (white or grey) or Flex 2K . Proceed by installing between the first and second layer of Flex 2K liquid waterproofer the self-adhesive butyl collar for floor drains type Floor Collar. Depending on the water exposure class, carry out the waterproofing with Flex 2K (two-component, applied in two layers with a construction trowel in a thickness not exceeding 2 mm each coat).

Waterproofing of components in contact with the ground (according to PG-MDS “Abdichtung von erdberührten Bauteilen”)

Waterproofing of buildings in contact with the ground, basic waterproofing and waterproofing of cross-sections inside and under walls according to DIN 18533, flexible twocomponent mineral waterproofing for walls and basements, foundations and concrete components against ground moisture, infiltration and pressure water accumulation.

1. Waterproofing of floor tiles and of external wall surfaces in contact with the ground against ground moisture (capillary water, adhesive water) and seepage water not accumulated and waterproofing of building foundations in areas subject to water splashes (water impact class W1-E according to DIN 18533-1).

2. Horizontal waterproofing inside and under the walls against capillary rising damp (water impact class W4-E according to DIN 18533-1).

3. Sealing of the building components in contact with the ground against the accumulation of seepage water and pressurised water up to 3 m of the water column at a maximum foundation depth of 5 m (water impact class W2.1-E according to DIN 18533-1).

4. Waterproofing of containers against water pressure from the inside (swimming pools, water tanks, water storage tanks, etc.) at their inside and outside up to a maximum filling height of 6 m (water impact class W2-B according to DIN 18535-1).

Waterproofing sludge can form with the possibility of cracking up to a maximum of 0.2 mm (bridging failure class R1-E according to DIN 18533-1 or R1 according to DIN 18535-1).

Types of substrates

They are suitable to concrete according to EN 206-1, minimum strength class C 20/25, plaster belonging at least to strength class CS III according to EN 998-1, brick and sand-lime masonry are suitable. Hollow bricks and hollow concrete blocks should be plastered with plasters belonging at least to strength class CS III according to EN 998-1. The substrate must be solid, largely flat and the surface must have fine pores. It must be free from nests, cracks and smudges, dust, water-repellent additives, mould oil, paints or other layers that may compromise adhesion. Fill the possible vents and gravel nests of the concrete substrate with Monorasante or restoration mortar Rinnova from the Torggler range.

Application and Implementation

Apply two coats of sealing grout obtained with Flex 2K so as not to exceed the maximum thickness of 2 mm of product. The joints between wall to wall, wall to floor and corners must be treated with polypropylene reinforcement tape with side perforations PP Tape 120 MM-50, reinforcement tissue for closed corners Corner Tissue 90° or reinforcement tissue for open corners Corner Tissue 270°. Flex 2K can be used to repair emerging and moving cracks in the substrate up to a maximum crack width of 0.2 mm.

Flex 2K must be stored in a dry and sheltered place. In the original closed bags Flex 2K component A will keep for at least 18 months. PROTECT FROM HUMIDITY. In the original closed tanks Flex 2K component B will keep for at least 12 months. PROTECT FROM FROST.

| Color | Code | Bicomponent | Packaging | Packaging size | Barcode |

|---|---|---|---|---|---|

| Grey | 6362 | 2 components | bag + canister | 25 kg + 8,5 kg |

| COMPONENT A | |

| Colour | grey |

| Consistency | powder |

| Bulk density (according to MIT 13)* | 1,40 g/l |

| Particle size (according to MIT 10)* | 0 – 0,5 mm |

| COMPONENT B | |

| Colour | white |

| Consistency | liquid |

| Bulk density | 1,01 kg/l |

| pH | 7 |

| Dry matter | 47% |

| FRESH MIXTURE VARIATIONS | |

| Components dosage: component A | 100 p.p. (1 bag of 25 kg) |

| Components dosage: component B | 34 p.p. (1 x 8.5 kg tank) |

| Consistence of the mixture | plastic – workable with trowel |

| Fresh mixture density | 1,80 kg/l |

| Mixture workability time | approx. 1 hour under normal conditions (at +20 °C) |

| Waiting time between coats | 4 to 6 hours depending on the porosity of the substrate and the environmental conditions |

| Full curing time | 28 days |

| Application temperature | from +5 °C to +30 °C |

| HARDENED PRODUCT VARIATIONS | |

| Operating temperature | from -20 °C to +90 °C |

| Tear resistance – adhesion for direct traction (according to DIN 24624) | 0,8 N/mm2 |

| Tensile strength at 23 °C and 50% r.h. (according to DIN 53455) – after 28 days | 1,0 N/mm2 |

| Tensile strength – 7 days at 23 °C and 50% r.h. + 21 days Immersion in water (according to DIN 53455) – after 28 days | 0,40 N/mm2 |

| Elongation % at break at 23 °C and 50% r.h. (according to DIN 53455) – after 28 days | 25,0% |

| Elongation % at break – 7 days at 23°C and 50% r.h. + 21 days immersion in water (according to DIN 53455) – after 28 days | 14,0% |

| Percentage reduction of elongation at break after 2000 hours of UV exposure (according to EN 1062-11) | 23,0% |

| Change in appearance after 2000 hours of UV exposure (according to EN 1062-11) | No bubble formation or cracking, no exfoliation. Exposed area colour variation. |

| Water vapour permeability – μ (according to EN 1015-19) | 500 |

| CO2 permeability – μCO2 (according to MIT 112) | 1000 |

| Waterproofing (according to DIN 1048)**: 28 days at 1.5 bar positive hydrostatic pressure | resists |

| Waterproofing (according to DIN 1048)**: maximum load under positive hydrostatic pressure | 3 bars |

| Waterproofing (according to DIN 1048)**: maximum load under negative hydrostatic pressure | 0.5 bars |

| HARDENED PRODUCT VARIATIONS EN 14891 | VALUES | REQUIREMENTS |

| Adhesion by initial traction*** (EN 14891 A.6.2) | 1.4 N/mm2 | ≥ 0.5 N/mm2 |

| Tensile adhesion after immersion in water*** (EN 14891 A.6.4) | 0.8 N/mm2 | ≥ 0.5 N/mm2 |

| Tensile adhesion after exposure to heat*** (EN 14891 A.6.5) | 2.2 N/mm2 | ≥ 0.5 N/mm2 |

| Tensile adhesion after freeze-thaw cycles*** (EN 14891 A.6.6) | 0.8 N/mm2 | ≥ 0.5 N/mm2 |

| Tensile adhesion after immersion in lime water*** (EN 14891 A.6.9) | 1.0 N/mm2 | ≥ 0.5 N/mm2 |

| Waterproofing according to EN 14891 A.7 | no penetration, weight increase 5 g | no penetration, weight increase ≤ 20 g |

| Crack bridging ability under standard conditions: (EN 14891 A.8.2) | > 1.73 N/mm2 | ≥ 0.75 N/mm² |

| Tensile strength after immersion in chlorinated water*** (EN 14891 A.6.8) | > 1.0 N/mm2 | ≥ 0.5 N/mm2 |

| Crack bridging ability at low temperatures (EN 14891 A.8.3) | 1.07 mm (-5 °C) 0.77 mm (-20 °C) |

≥ 0.75 N/mm² |

| Certification (EN 14891) | CM O2 P | |

| VARIATIONS ACCORDING TO EN 1504-2 | VALUES | REQUIREMENTS |

| Permeability to water vapour (EN 7783) | SD = 5.8 (thickness 2 mm) | Class II (5 m ≤ SD ≤ 50 m) |

| Capillary absorption and permeability to water (EN 1062-3) | w = 0.03 kg/m2*h0.5 | w < 0.1 kg/m2*h0.5 |

| Ultimate tensile strength (EN 1542) | 1.3 MPa (on dry concrete) | with no traffic load: > 0.8 MPa |

| Ultimate tensile strength (EN 1542) | 1.3 MPa (on dry concrete) | with traffic load: >1.5 MPa |

| Permeability to CO2 (EN 1062-6 Method A) | SD (CO2) = 380 m | SD > 50 m |

| Crack resistance (EN 1062-7 Method A; static) | 1.026 mm (23 °C) | Class A3 (23 °C) |

| Crack resistance (EN 1062-7 Method A; static) | 0.850 mm (-10 °C) | Class A3 (-10 °C) |

| Crack resistance (EN 1062-7 Method A; dynamic) | No crack formation after 1000 passages, maximum width 0.30 mm | Class B3.1 (23 °C) |

| Artificial ageing (EN 1062-11) | No swelling, cracking and flaking; colour change (lighter). Chalking | No swelling, cracks, crumbling. Slight change of colour for loss of brilliance and can chalk easily, but the variation must be described. |

* Torggler’s Internal Methods (MIT) are available on request.

** According to the specifications, the parameters have been determined with the amount of water required to obtain a consistency of 21 ± 1 cm (consistency workable with trowel).

*** Values obtained with cement-based adhesive type C2 according to EN 12004 (Tile 700 + Flex diluted 1:1).

The total consumption of Flex 2K comp. A + comp.B is about 1.7 kg/m per mm of thickness.

Contact our team for personalized support and product guidance.