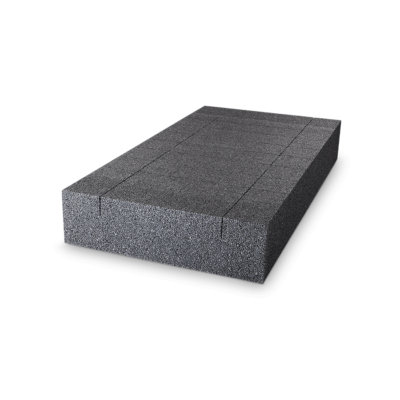

Varitherm is an EPS building material with excellent mechanical compactness, high thermal insulation, high density and resistance to waterlogging. These properties are decisive criteria for various applications and thus guarantee a wide range of uses: insulating and compact underlay for laying the Bridge Mat 1000 mm 50 m waterproofing system; for the correction of thermal bridges in window frames. The panels are made from a block that is cut to size with a hot wire. The standard size of Varitherm thermal insulation panels is 1200×800 mm, with thicknesses from 10 mm. Specific weight 140 kg/m³.

Instructions for use

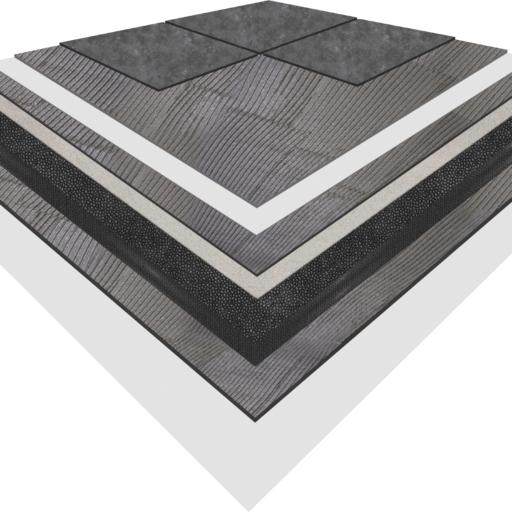

Varitherm in combination with Bridge Mat 1000 mm – 50 m must be applied in accordance with the following guidelines:

The substrate to be treated must be solid and completely clean, with a sufficient slope of at least 1% to facilitate water drainage to the outside or to designated collection points. All cement residues, loose parts, and any traces of dust and/or grease and/or release agents must be removed.

Before installing Varitherm on concrete substrates (concrete slabs, cement screeds), it is necessary to check that the surface is sufficiently even. Cavities, irregularities, gravel nests, and excessive porosity must be repaired, and the surface level restored using Multimix EVO, a fiber-reinforced, rapid-setting cement mortar.

Apply Multigrip on both sides of Varitherm 24 hours prior to installation. Multigrip is a universal, single-component bonding primer based on styrene-acrylic resins in water dispersion with inorganic fillers, designed to make the surface rough and improve adhesion.

Installation of the boards is carried out using Tile 480 Grey, an improved, single-component, high-strength cement-based adhesive with extended open time and deformability, classified as C2 TE S1 according to EN 12004.

The boards must be laid with a joint of approximately 3 mm, and all vertical elements such as walls, parapets, stairs, and columns must be sealed with Low Modulus, a neutral silicone sealant with a very low elasticity modulus for façades and floors.

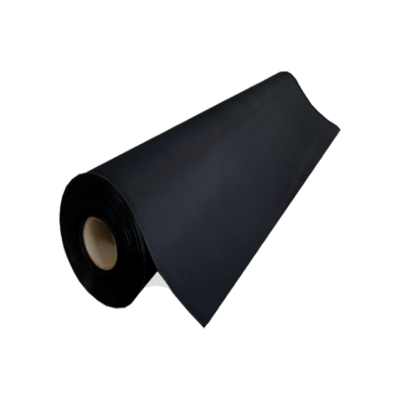

Continue with the installation of Bridge Mat 1000 mm – 50 m, a waterproof, decoupling membrane.

Using a 6-mm notched trowel, apply a layer of Tile 480 adhesive onto the substrate and embed the membrane into the still-fresh mortar. Smooth the installed sheet with a trowel toward the edges, ensuring that any air pockets, residues, or overlaps are removed. When laying the Bridge Mat 1000 mm – 50 m into the adhesive, the sheets should be installed in one direction and side by side.

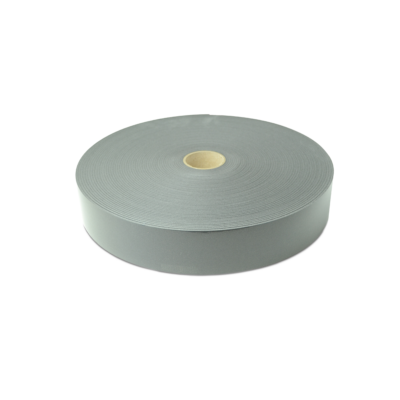

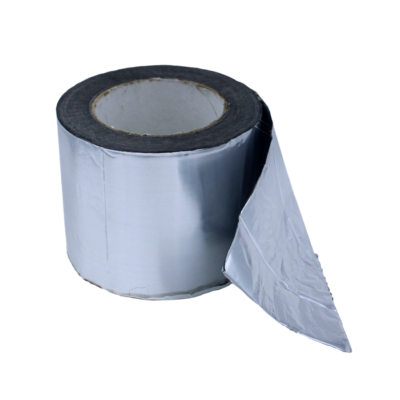

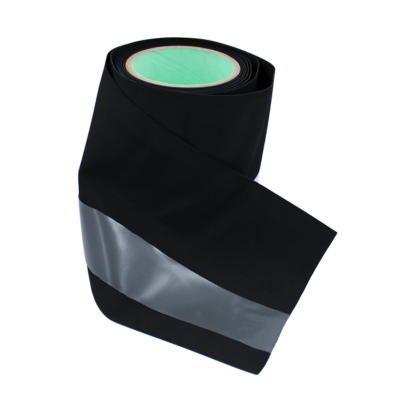

At the joint areas, the sheets must be sealed with a suitable reinforcement tape, such as PP Tape from the Torggler range. For this purpose, use the Aquatech liquid waterproofing membrane or the cement mortars Flex 2K or Flexistar, embedding and smoothing the PP Tape to eliminate air pockets.

At floor/wall junctions, the above-mentioned reinforcement tape must be used, or, in areas with closed angles, the 90° corner fabric, and in areas with open angles, the 270° corner fabric, also embedded in the Aquatech liquid waterproofing membrane or in Flex 2K or Flexistar cement mortars.

Wait at least 24 hours to allow the Tile 480 adhesive to fully cure.